Tools and equipment help carry out things and tasks a lot easier. This is also the reason why they were invented in the first place. Different types of machines have been created since ancient times. One of the oldest forms of machines is the screw conveyors. It is these things that are used to lift water in the old days. This design has been carried out and is still being used even up to this day. Although there have been some modifications, the basic concept of this one still remains the same. This compact, efficient and simple machine retains the same concept that it has since it was invented. Most of the time, you will be able to see the conveyor screws that will be fixed through a trough. This machine usually rests horizontally on the floor or on saddles. You can even find some that are placed on their own feet. Conveyor screws usually will have covers in them. This machine also has different pulp and paper screw conveyors which can include couplings, shrouds, spouts, flange, through inside and bearings. What you can see moving is the screw. Once materials are fed up in it then it will pick it up and conveys it to the other end as it rotates. The feeding and discharge of various materials can be controlled using gates.

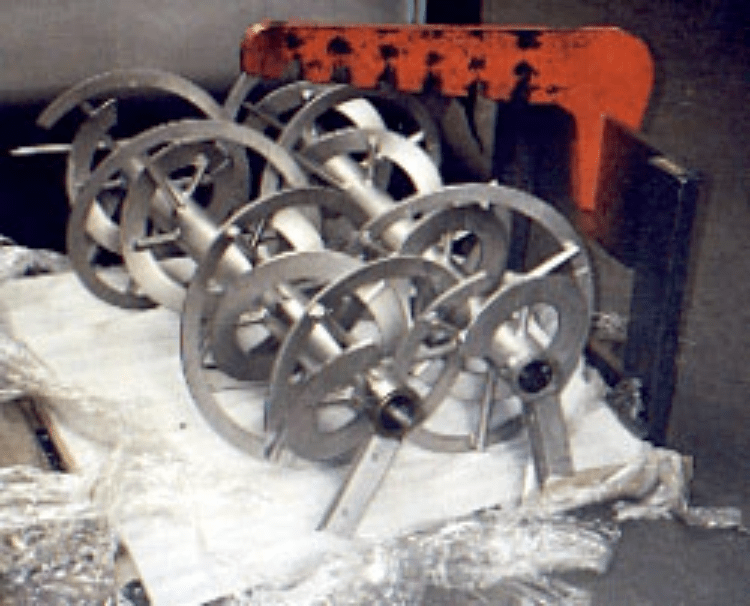

In this day and age, it is the conveyor screws that are being used in order to handle bulk dry materials. The trough that the machine has will help protect the materials from dust and other contamination. You can find different types of screws being used. You can either opt for the shafted or the non-shafted ones. It is also these screws that come in varying sizes depending on your requirements. Conveyor screws are usually being used in order to move different materials in a straight line or slightly angled. You can also utilize multiple screws for different applications. Once you are considering conveyor screws then you can opt for varying materials hic can include nylon, Teflon, or stainless steel. There are also manufacturers that make use of brass or aluminum. The screws usually are treated with anti-corrosive chemicals. This means that the screws will last longer and maintenance will also be minimal.

You can find unconventional conveyor screws in the market and one of them is the flexible conveyor screw. This is also being referred to as a spiral conveyor. The screws are specific in their usage and that is the reason why they need to be custom made. It is important though that certain aspects of the operation will be considered to ensure that the requirements are provided. A flexible conveyor screw is one that can carry materials at different angles. It can also be used in a horizontal and vertical position.

Whatever type of conveyor screw you will be choosing, you can be sure that they will be efficient. Another great thing about these machines is that they are also easy to install and operate. The running cost is also low which is also an advantage. You need to ensure though that you will be buying conveyor screws from reputed manufacturers to ensure their quality.